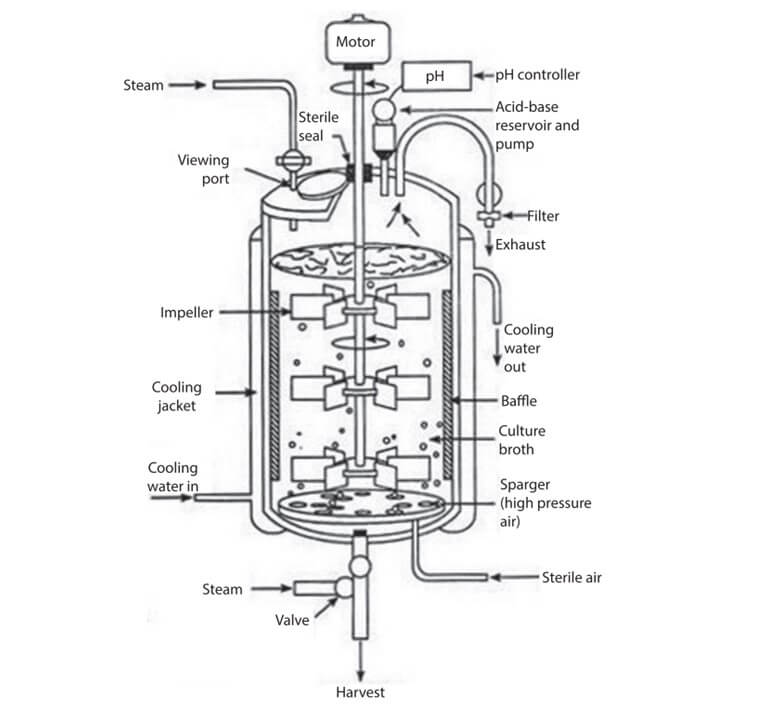

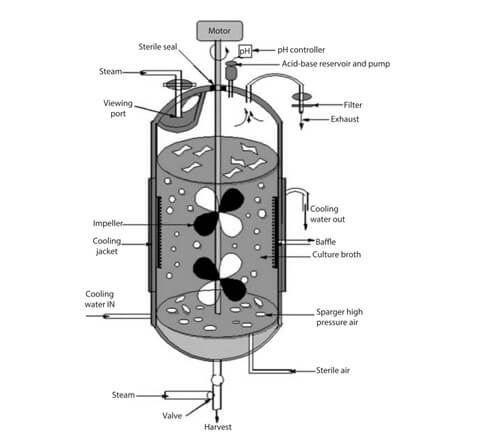

It is a closed container with adequate arrangement for aeration, agitation, temperature and pH control, and drain or overflow vent to remove the waste biomass of cultured microorganisms along with their products.

A bioreactor should provide for the following:

Bioreactors are used for the production of biomass, metabolites, and antibiotics.

Table of Contents

Interesting Science Videos

The fermentor (bioreactor) types used extensively in industries are

Some important applications of the bioreactor are:

| Type of bioreactor | Applications |

| Stirred tank fermenter | Antibiotics, citric acid, Exopolysaccharides, cellulose, Chitinolytic enzymes, Laccase, Xylanase, Pectic, and pectate lyase, Tissue mass culture, Lipase, Polygalacturonases, Succinic acid |

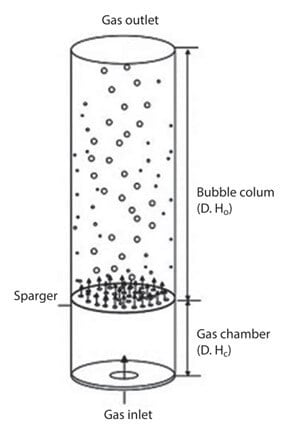

| Bubble column fermentor | Algal culture, Chitinolytic enzymes |

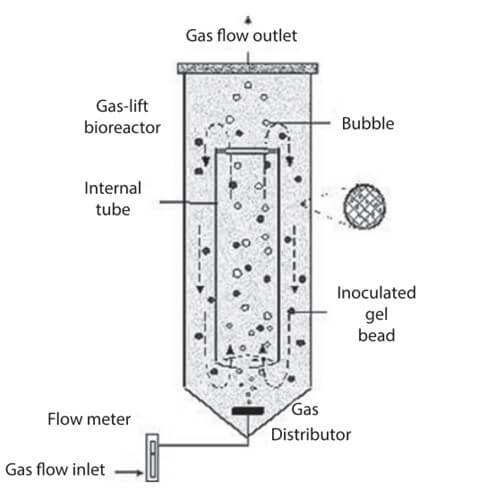

| Airlift fermentor | Antibiotics, Chitinolytic enzymes, Exopolysaccharides, Gibberelic acid, Laccase, Cellulase, Lactic acid, Polygalacturonases, Tissue mass culture |

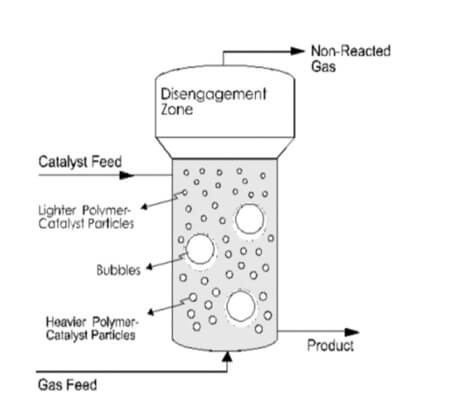

| Fluid bed fermentor | Laccase |

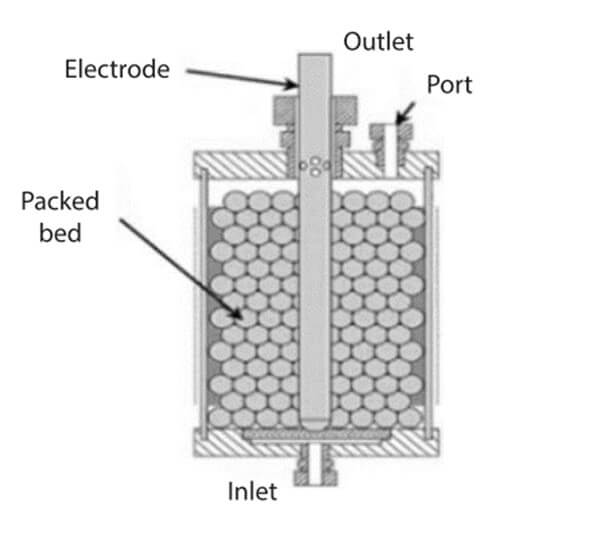

| Packed bed fermentor | Laccase, Hydrogen, Organic acids, Mammalian cells, |

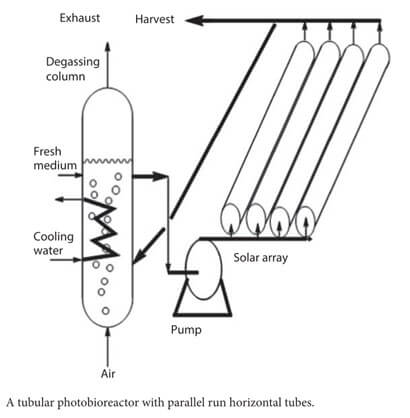

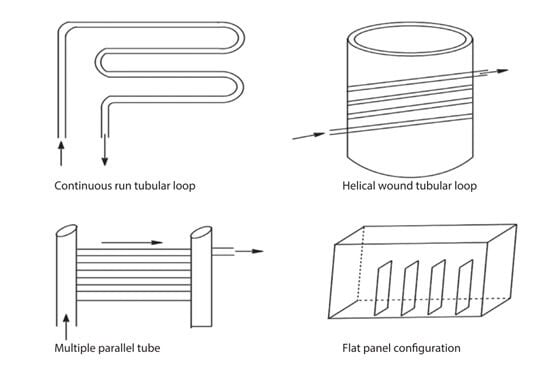

| Photobioreactor | Wastewater treatment, water quality management, remediation of contaminated soil |

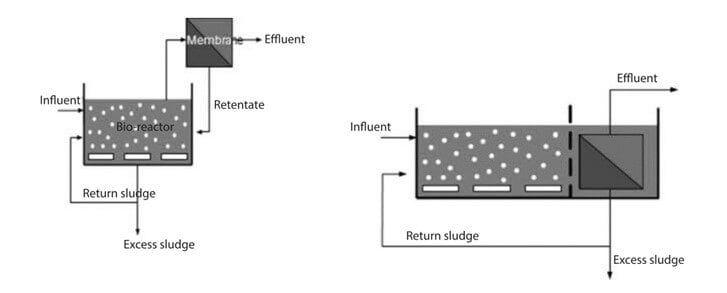

| Membrane bioreactor | Alginate, Antibiotic, Cellulose hydrolysis, Hydrogen production, Water treatment, VOCs treatment |

| Types of bioreactor | Limitation |

| Stirred tank fermenter | High shear stress |

| High power consumption | |

| Moving internal parts | |

| Bubble column bioreactor | Low photosynthetic efficiency |

| Airlift | Non-uniform nutrient supply |

| Insufficient mixing | |

| High viscosity can limit bulk circulation | |

| Fluid bed fermentor | Particle (breakup) is common |

| Increased reactor vessel size | |

| Bubbling beds of fine particles are difficult to predict and are less efficient. | |

| Pipe and vessel walls erode due to collisions by particles | |

| Packed bed bioreactor | Undesired heat gradients |

| Poor temperature control | |

| Difficult to replace the catalyst | |

| Photobioreactor | Salability problems |

| Require temperature maintenance as they lack evaporative cooling | |

| Periodic cleaning due to light exposure | |

| Need maximum light exposure | |

| Membrane bioreactor | Biofilm overgrowth leads to periodic cleaning |

| The membrane can rupture at high flow rates |

About Author

Sanjogta Thapa Magar has done Master’s degree (M.Sc.) in food microbiology from St. Xavier’s college. Currently, she is working as a Quality control microbiologist in the pharmaceutical industry. She is particularly interested in studying the antimicrobial property found in food.

Hi really very informative and please send me the soft copy 2004.dinesh@gmail.com

Regards

Dinesh Reply

Hi Sanjogta,

Thank you so much for sharing the information. I am looking for real bioreactor data for batch process use case to train my machine learning model. Please advise if you could help on getting a data set like that. Thanks again,

Ashraf Suri

email: ashraf.suri@msn.com Reply